No Item in Cart

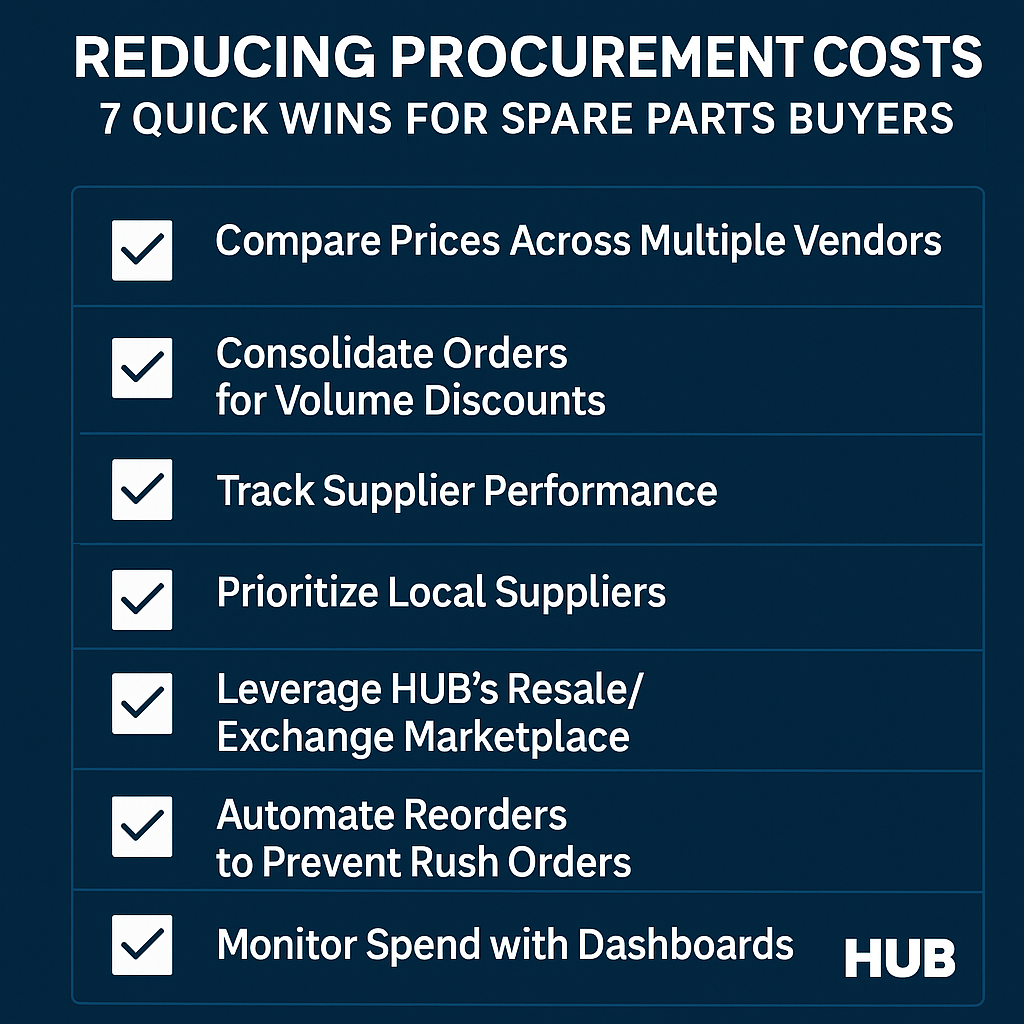

Reducing Procurement Costs: 7 Quick Wins for Spare Parts Buyers

Introduction

Spare parts procurement can quietly drain your budget if not carefully managed. While strategic overhauls are great, sometimes you need quick, actionable wins that make an immediate impact.

In this post, we share 7 proven strategies to reduce procurement costs — and explain how HUB’s vendor comparison and bulk deal features make it easy to save without sacrificing quality.

🚀 7 Quick Wins to Cut Procurement Costs

1️⃣ Compare Prices Across Multiple Vendors

- Never settle for the first quote. Use HUB’s real-time vendor comparison tool to find the best price without sacrificing quality.

2️⃣ Consolidate Orders for Volume Discounts

- Bundling purchases allows you to unlock bulk pricing. HUB helps you group orders across departments to maximize savings.

3️⃣ Track Supplier Performance

- Reliable vendors save money in the long run. HUB’s analytics track delivery speed, quality, and service levels so you avoid costly

mistakes.

4️⃣ Prioritize Local Suppliers

- Cut freight costs and lead times by sourcing locally when possible. HUB filters suppliers by location to help you find nearby

options.

5️⃣ Leverage HUB’s Resale/Exchange Marketplace

- Turn stagnant stock into cash or trade value using HUB’s resale and exchange system — a hidden cost-saving opportunity.

6️⃣ Automate Reorders to Prevent Rush Orders

- Avoid costly emergency orders by setting dynamic reorder points in HUB, ensuring you always restock on time.

7️⃣ Monitor Spend with Dashboards

- Use HUB’s spend tracking dashboards to spot overspending patterns and adjust your procurement strategy in real time.

✅ Conclusion

- Cutting procurement costs doesn’t have to mean cutting corners. With HUB’s tools — from vendor comparison to bulk deals and

smart reordering — you can keep your plant running efficiently while protecting your budget.

🔗 Explore HUB’s Cost-Saving Tools: www.HUBspareparts.com

🔗 Book a Demo of HUB’s Vendor Comparison Engine: Contact Us