No Item in Cart

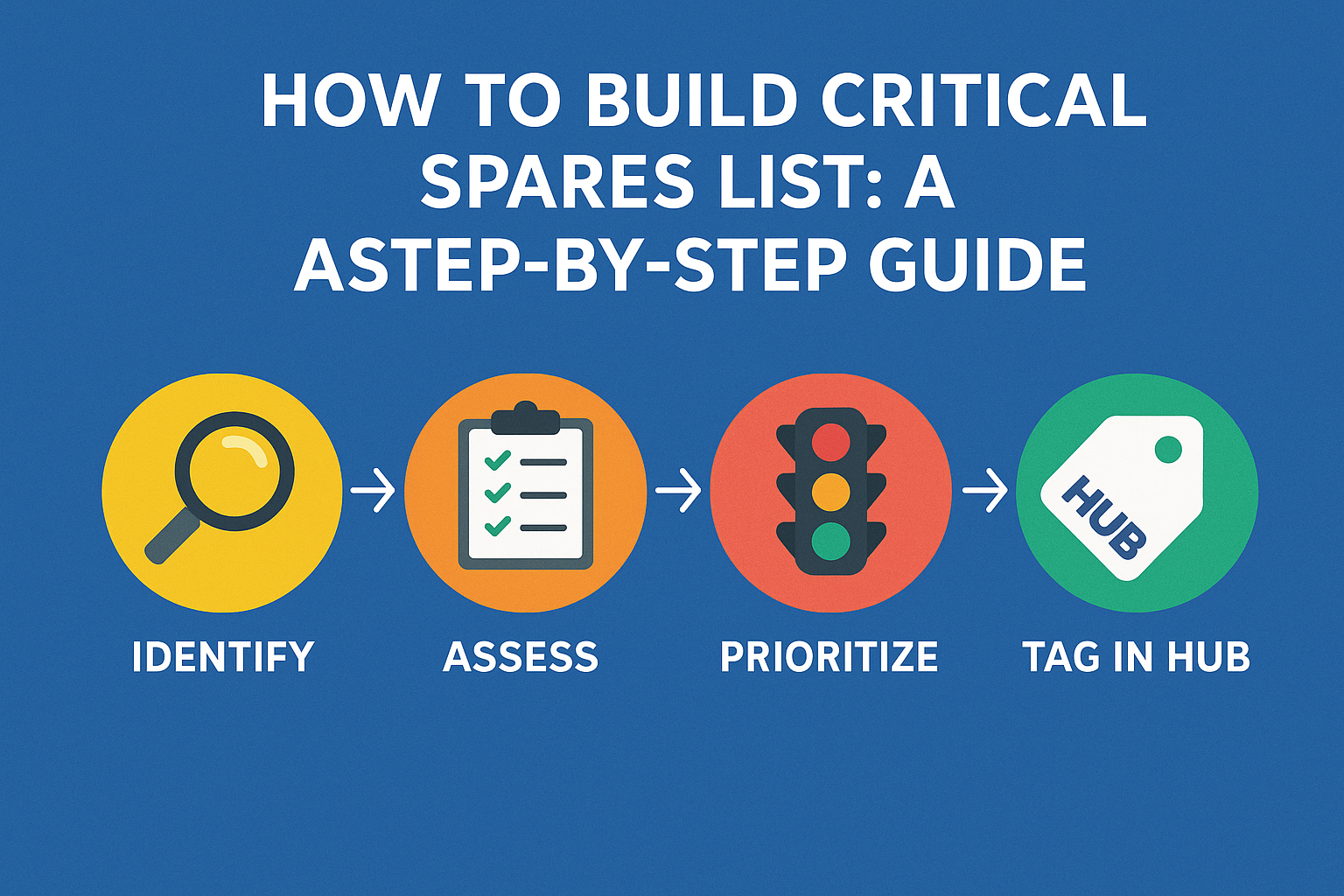

How to Build a Critical Spares List: A Step-by-Step Guide

Introduction

A single missing part can halt production — but keeping everything in stock isn't practical. That’s why every plant needs a critical spares list: a prioritized catalog of parts that are essential for continuous operations.

In this step-by-step guide, we’ll show you how to build your list and explain how HUB’s tagging feature keeps it dynamic, searchable, and integrated with your procurement workflows.

🛠️ Step 1: Define ‘Critical’ for Your Operations

- Critical spares are usually:

- Required for safety or compliance

- Difficult to source quickly (long lead time)

- Essential for key equipment with no redundancy

- High cost of downtime if missing

🔍 Step 2: Map Your Equipment & Failure Modes

- List major assets and break down:

- Common failure points

- MTBF (Mean Time Between Failures)

- Historical data on part replacements

🗂️ Step 3: List Potential Spare Parts

- Catalog all components related to each asset — from motors and sensors to belts and fuses.

🚦 Step 4: Prioritize Based on Risk & Impact

Rate each part by:

- Criticality score (impact on production)

- Availability (lead time)

- Cost (replacement price vs. downtime risk)

- Use a simple matrix to decide which parts make your critical list.

🧩 Step 5: Validate & Review Regularly

Involve engineers, maintenance managers, and procurement teams to validate the list. Schedule reviews (e.g., annually) to update it based on changes in equipment or operations.

🚀 How HUB Enhances Your Critical Spares List

✅ Smart Tagging: Mark items as “Critical” in HUB for easy filtering and fast reorder alerts.

📊 Dynamic Dashboards: Track the health and stock levels of critical spares at a glance.

🔔 Priority Alerts: Get notified instantly when critical parts fall below safety stock.

📦 Vendor Tracking: Link critical parts with top-performing suppliers for faster sourcing.

🔁 Workflow Integration: Ensure all purchase requests for critical parts follow expedited workflows.

✅ Conclusion

Building a critical spares list is a must for operational resilience. With HUB, you can create, manage, and act on your critical parts list seamlessly — keeping your plant running no matter what.

🔗 Start Tagging Critical Spares in HUB: www.HUBspareparts.com

🔗 Book a Free Demo for Critical Parts Management: WhatsApp Chat